machining surface finish callout

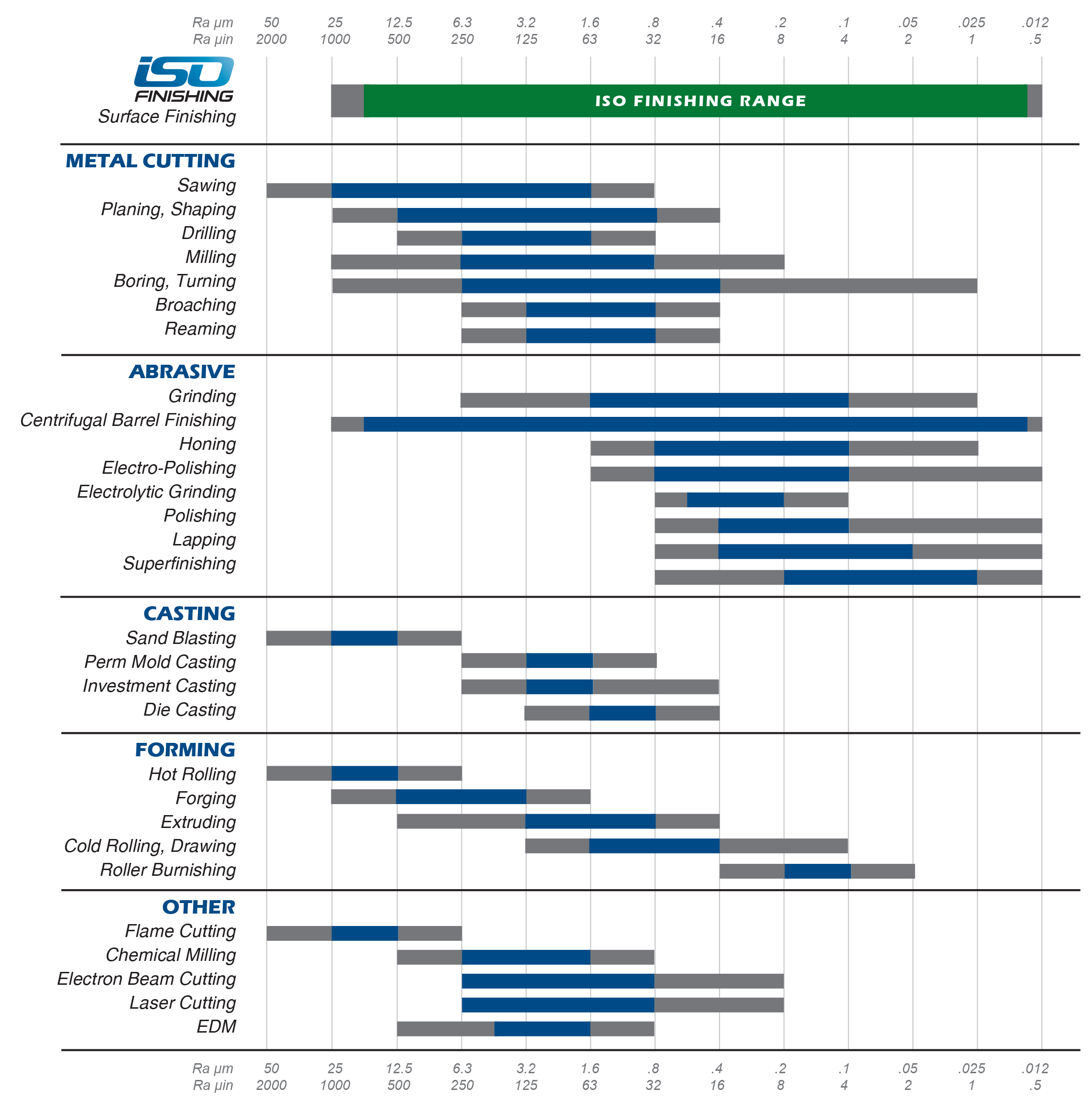

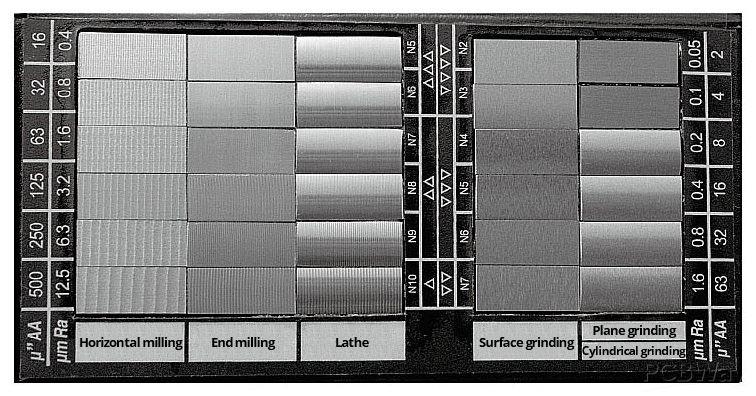

Surface texture obtained by the removal of material by machining operations like turning drilling milling etc. Surface finishing is the last phase of the CNC machining process.

Surface Roughness Symbols Grade Numbers Indication Terminology And Calculation Cnclathing

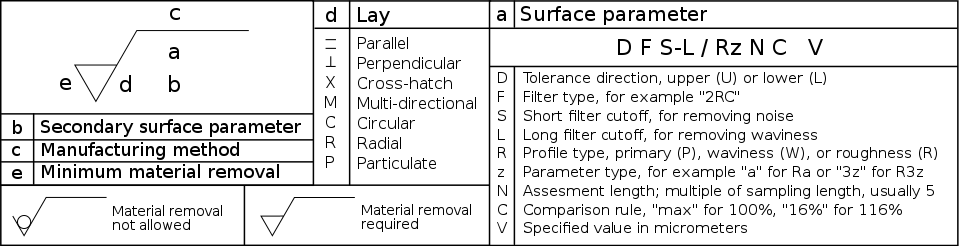

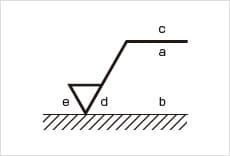

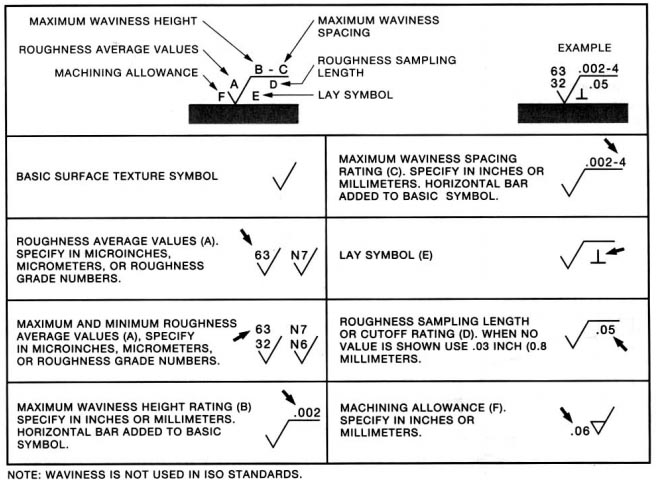

There are many variations of the surface texture symbol but most often it is used with a microinch or.

. The tick symbol is placed on the surface or an extension drawn to it. Surface finish specification and comparison. Finish Symbol N Finish R a μinch R a μm Super finishing.

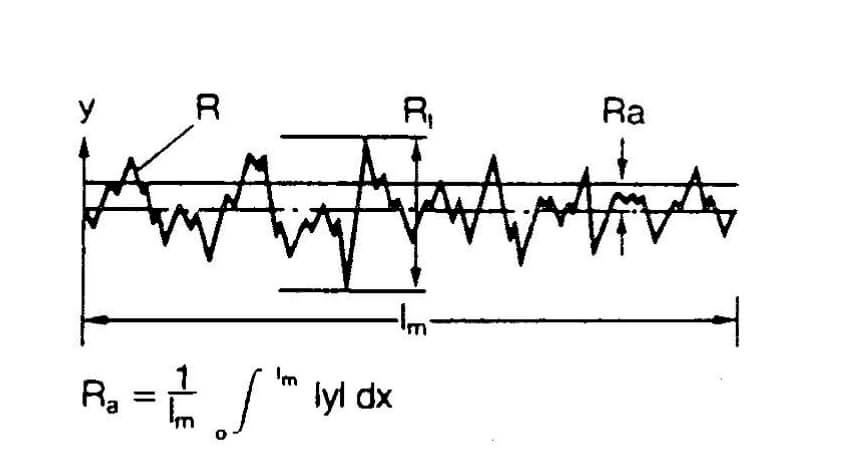

It is a means of altering material surfaces through processes involving adding. The nature of a surface is known as surface finish or surface topography. Measuring surface finish is also referred to as surface metrology.

If the part is metric then the 82 most likely means an 82 micron Ra finish. An easy way to convert metric surface call outs to standard US. Surface finish refers to the process of altering a metals surface that involves removing adding or reshaping.

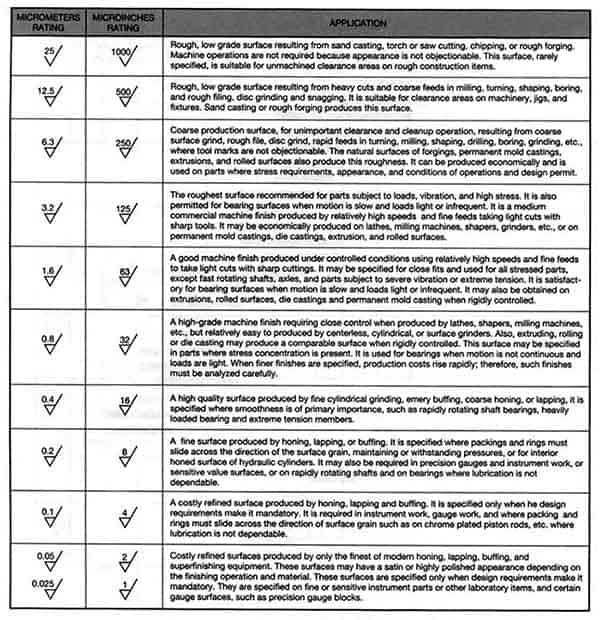

Surface finish is a parameter that determines the physical characteristics appearance of a component. Surface Finish Symbols and Callouts. For example 16 63 rms 32 125 rms and 63.

It is a measure of the complete texture of a products surface that is defined by. Surface Texture A symbol for defining the surface finish of a part. The tick symbol is placed on the surface or an extension drawn to it.

It is an important part of many fields and is mostly known for the CNC machining of precision parts and assemblages. Ones rms is to mentally multiply the metric value by 40. N1 1 0025 Lapping.

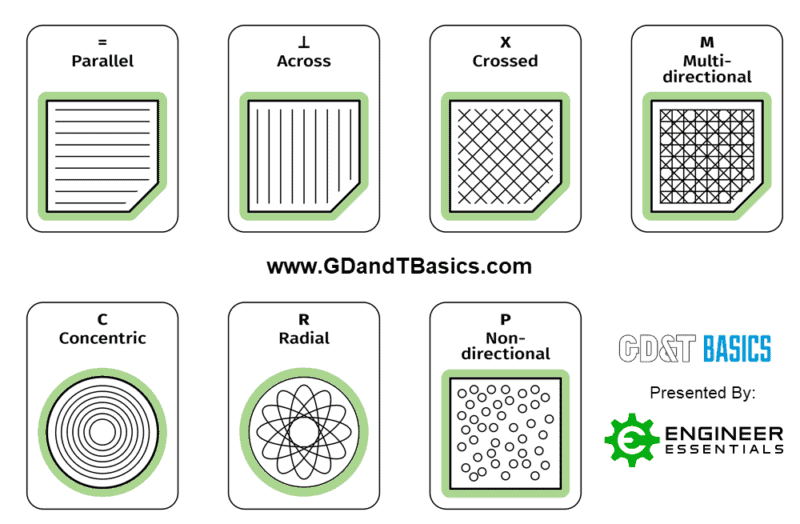

A callout on a drawing of a minimum surface finish is normally to insure buddy machining it who is under the gun isnt going to finish it with a 020rev federate on looser specs. If it is a turned surface then the C probably denotes a circular lay to the finish. This symbol has a circle added in the groove of the basic shaped.

Machining surface finish callout. These units areMachining Surface Finish Chart Conversion Comparator Method Degree Ra Rz RMS nd Average Roughness Ra. The details in iso.

If its an inch print. You can use surface finishing to remove defects and flaws from parts and improve their appearance boost resistances from. It refers to a surfaces minor local deviations from a perfectly flat surface an actual plane.

Machining N9 250 63 N10 500 125 Rough.

Surface Finish Texture Symbols Drafting Gd T Simpliengineering

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

What Is Surface Finish Units Symbols Chart Engineering Choice

Surface Roughness Symbol In Drawings Mechanical Engineering General Discussion Eng Tips

Surface Finish Symbols Taylor Hill S Drafting E Folio

Complete Surface Finish Chart Symbols Roughness Conversion Tables

The Basics Of Surface Finish Gd T Basics

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Roughness Chart Comparison Iso Finishing

Surface Finish Texture Symbols Drafting Gd T Simpliengineering

Surface Finish Surface Roughness Symbols Charts Callouts Costs

Surface Finish Texture Symbols Drafting Gd T Simpliengineering

The Basics Of Surface Finish Gd T Basics

Surface Finish Quality Ra Rz Rt Surface Roughness Measuring Finish

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Indications On Drawings Surface Metrology Guide Digital Surf